How to Confirm That You Have Found a Reliable Ceramic Manufacturer

Introduction:

Selecting a reliable ceramic manufacturer is a pivotal decision that can significantly impact the success of your project. You are in the business of creating intricate ceramic art pieces. In this comprehensive guide, we will delve into the intricacies of confirming the reliability of a ceramic manufacturer, providing you with a roadmap to make informed decisions that align with your quality and production requirements. Only by establishing long-term cooperation with ceramic factories can we get better assistance in subsequent procurement and design.

Initial Research and Background Check

The foundation of any successful partnership begins with thorough research and a background check. Start by creating a list of potential ceramic manufacturers and delve into their reputations within the industry. Examine their track record, industry experience, and client testimonials. A reliable manufacturer should boast a positive history of delivering quality products consistently and meeting deadlines.

Additionally, check for industry certifications and standards adherence. Manufacturers who are committed to quality will often be certified by relevant organizations. This initial research will help you filter out candidates that do not meet your standards, allowing you to focus on those with a proven commitment to excellence.

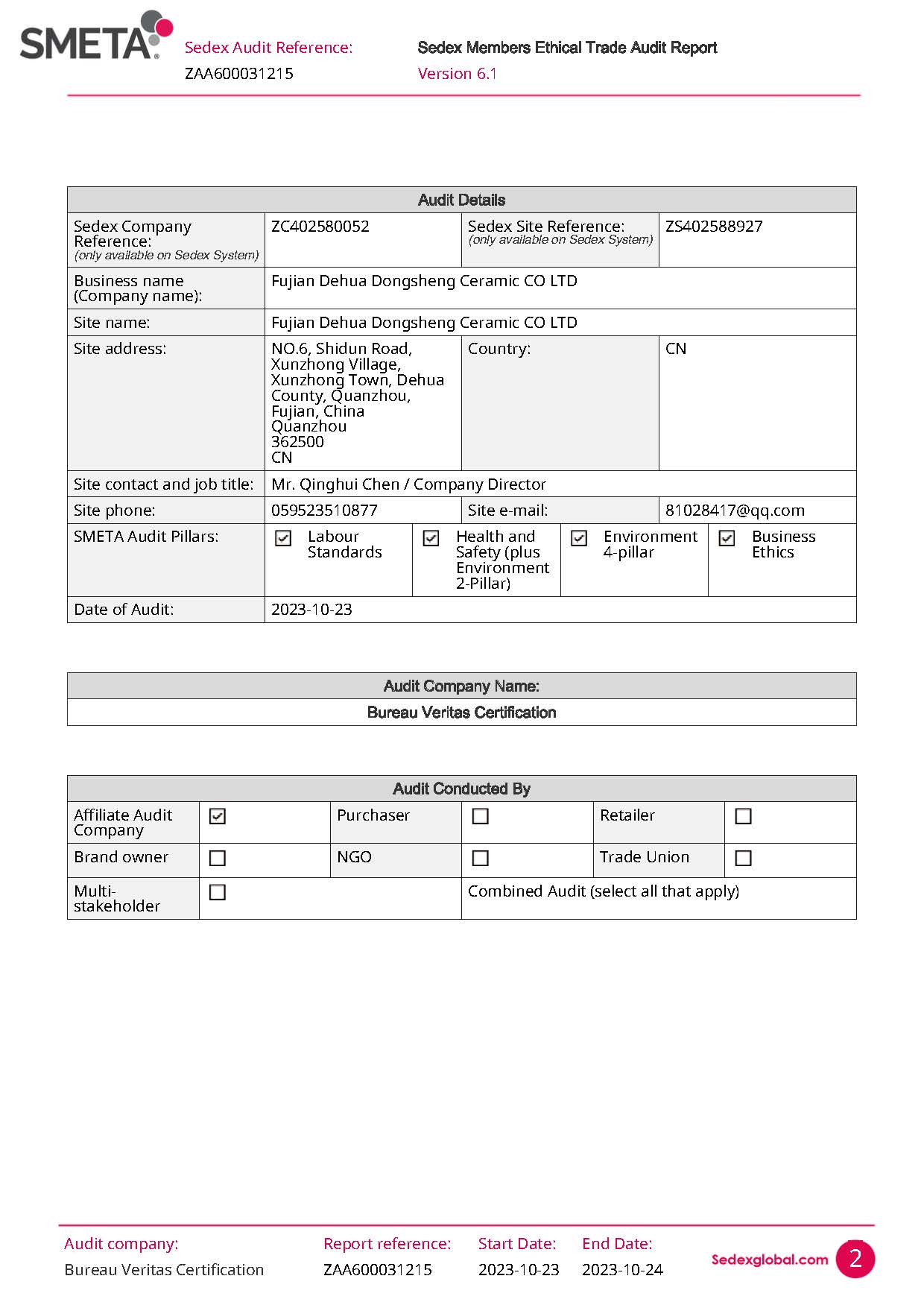

Often large supermarkets require SEDEX/BSCI factory inspection first when purchasing. Although this is part of the supermarket purchasing process. But we can also see how Supermarket selects reliable factories. Every year we re-test SEDEX factory audits. The picture below is the home page of this year’s SEDEX report.

Understanding Manufacturing Processes

The next step in confirming a manufacturer's reliability is gaining an in-depth understanding of their manufacturing processes. Inquire about the raw materials they use, their firing techniques, production time of each process and the quality control measures implemented throughout the production chain. A manufacturer committed to transparency will readily share details about their processes, emphasizing their dedication to producing ceramics that meet standards.

Understanding the manufacturing processes is crucial for ensuring the durability, functionality, and aesthetic appeal of the final ceramic products. It also allows you to assess whether the manufacturer can accommodate any specific customization requirements you may have for your project.

On-Site Visit to Manufacturing Facility

Whenever feasible, schedule a visit to the manufacturing facility. This on-site inspection provides invaluable insights into the working conditions, quality control measures, and overall efficiency of the operation. Pay attention to the organization and cleanliness of the facility, as these factors often correlate with a manufacturer's commitment to producing high-quality ceramics.

During the visit, engage with the production team, ask questions, and observe the manufacturing processes firsthand. This direct interaction will allow you to assess the manufacturer's dedication to quality and their ability to meet your specific project requirements.

The square number of samples and the number of samples can largely evaluate the strength of the factory and the number of factory customers. The number of customers can reflect the quality of the factory.

Requesting and Evaluating Product Samples

One of the most effective ways to confirm the reliability of a ceramic manufacturer is by requesting and evaluating product samples. These samples offer a tangible representation of the manufacturer's capabilities and the quality of their products. Pay close attention to details such as glaze consistency, color accuracy, and overall craftsmanship.

Evaluating product samples also allows you to assess the manufacturer's flexibility in meeting your specific design or material requirements. It's an opportunity to identify any potential issues early in the process and ensures that the final products align with your expectations.

The process of making samples in our factory is to confirm with customers at every step. Such as sculpture confirmation once. The embryo body is confirmed once. Confirm once before final shipment. If the customer is not satisfied after receiving the goods, we can re-make them. If there is any dissatisfaction along the way, it can be modified. In this way, we can achieve the product effects that customers want to the greatest extent.

Quality Control Measures

A reliable ceramic manufacturer should have stringent quality control measures in place throughout the production process. Inquire about their quality assurance procedures, including regular inspections at various stages of production. This commitment to quality control minimizes the risk of defects and ensures that each batch of ceramics meets the specified standards.

Communication and Customer Service

Effective communication is a cornerstone of any successful business relationship. Assess the responsiveness and professionalism of the manufacturer's team. A reliable manufacturer should be willing to address your inquiries promptly, provide regular updates on the production process, and be open to collaborative discussions.

Fast and clear communication not only fosters a positive working relationship but also ensures that any concerns or changes in requirements can be addressed in a timely manner. Evaluate the manufacturer's commitment to customer service, as this is indicative of their overall reliability.

Whether a reasonable and effective solution can be proposed every time a problem arises is also a very important consideration.

Control of delivery progress

On-time delivery is an important consideration for many customers. Because many projects are seasonal. There is timeliness. Delayed delivery times can easily result in lost customer sales.

As a large ceramic supplier, ceramic factory. We have long-term cooperation with suppliers such as Walmart, ALDI, Paladone, etc. It can also be seen that we are highly concerned about delivery time.

Conclusion

In conclusion, confirming the reliability of a ceramic manufacturer is a multifaceted process that requires careful consideration of various factors. From initial research and background checks to on-site visits, product sample evaluations, and assessments of quality control measures, each step contributes to a comprehensive understanding of the manufacturer's capabilities.

By following this guide and investing the time and effort required to vet potential partners, you can make informed decisions that align with your project's goals and quality standards. A reliable ceramic manufacturer is not just a vendor but a strategic partner in your success, contributing to the longevity and success of your ceramic products in the market.

评论

发表评论